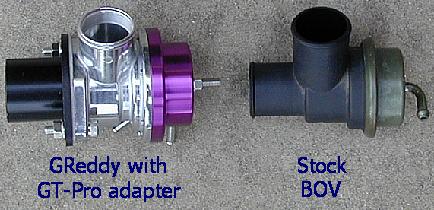

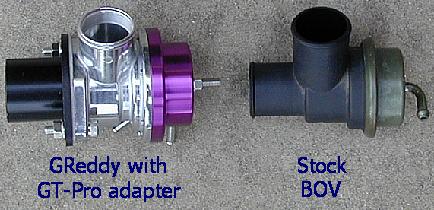

Stock and GReddy Type-S By-Pass Valve

in the Mitsubishi 3000GT and Dodge Stealth

by Jeff Lucius

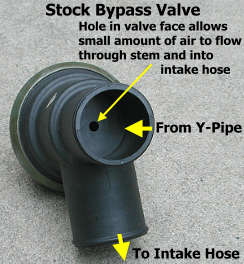

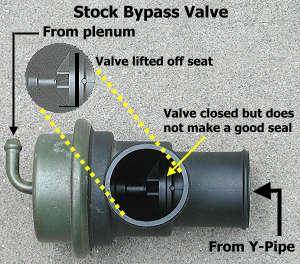

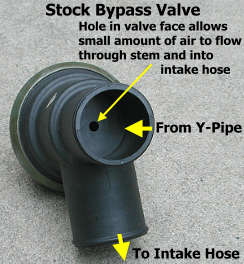

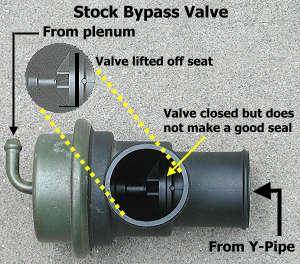

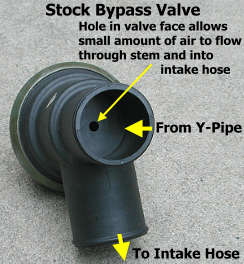

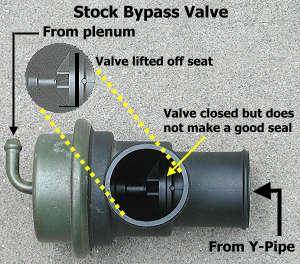

Problem with stock BPV: Why replace the stock by-pass valve (BPV)? Because it leaks. It is designed to leak. As shown in the pictures below, there is a hole in the face of the valve that is designed to allow air to flow at all times from the Y-pipe through the valve stem and into the intake hose. Another design "feature" is the plastic valve and seat. These two parts do not fit together tightly and there is no rubber seal. So air leaks around the valve face and into the intake hose. To determine this, I lit a match and extinguished it, filling the opening of the BPV from the Y-pipe with smoke from the match. Without creating any pressure I could see the smoke leak past the valve. Mitsubishi probably thinks a "leaky" BPV is a safety feature, and it might be in order to limit boost somewhat in a car that is stock except for an owner-installed boost controller. However, for the owner that likes more precise control of the by-pass air, an aftermarket valve is preferable. The GReddy Type-S BOV is one choice. GReddy suggests using the Type-R BOV for engines producing over 400 HP. However, the Type-S BOV has worked well for many 3000GT/Stealth owners, holding boost to at least 20 psi (something like 500 HP or so).

Internal workings of GReddy BOV: 2-greddy-bov-anatomy.htm

Function: This device GReddy calls a blow-off valve (BOV) is really a by-pass valve. Its functions are to prevent or reduce compressor surge and to decrease turbo spool-up time between shifts.

Compressor Surge:Typically, surge occurs immediately after the throttle plate is closed while the turbocharger is spinning rapidly, such as between shifts or when decelerating. During surge, air pressure increases between the throttle body and the compressor, which reduces the air flow at the compressor. If the air flow falls below a certain point, the compressor wheel (the impeller) looses its "grip" on the air. Consequently, the air in the compressor stops being propelled forward by the impeller and is simply spinning around with the wheel, which is still being rotated by the exhaust gas passing through the turbine section. When this happens, the pressure build-up at the discharge opening forces air back through the impeller causing a reversal of air flow through the compressor. As the back pressure eventually decreases, the impeller again begins to function properly and air flows out of the compressor in the correct direction. This sudden air-flow reversal in the compressor can occur several times and may be heard as a repetitive "WHEw Whew whew" noise if the surge is mild to a loud banging noise when surge is severe. Surge should be prevented at all costs because it not only slows the turbocharger wheels so that they must be spooled back up again but because it can be very damaging to the bushings or bearings and seals in the center section of the turbo.

Connections and Operating Principle:The BPV has three hose connections: to the Y-pipe (can be pressurized), to the intake hose (never pressurized), and to the plenum (can be pressurized or at vacuum). When the pressure in the plenum (sensed from the small hose connected to the "straight" nipple) is less than the pressure in the Y-pipe (big hose at the base) by a certain amount, the BPV allows pressurized Y-pipe air to go into the intake hose just after the mass-air sensor (MAS). The small angled nipple allows air pressure to equalize in a (relatively) confined space inside the valve body used by the internal diaphragm; it should be left open and not capped or connected to anything. Unlike the stock BPV, the GReddy valve allows you to adjust what the pressure difference must be between the plenum and Y-pipe before before the valve drains air from the Y-pipe into the intake hose to prevent surge.

Adjusting: The screw on the end of the purple cap adjusts the tension on the internal spring. To change this tension, start by loosening the lock nut with a 10-mm wrench. Using a 3-mm hex key inserted into the end of the screw, turn the screw clockwise to increase tension (the screw will go down a little into the purple cap), or counterclockwise to reduce tension. Be sure to tighten the lock nut when finished.

Increasing the tension ("tightening" the valve) will increase the pressure difference that must exist between the plenum and Y-pipe (that is, the pressure on either side of the throttle body) before the valve opens. Decreasing the tension ("loosening" the valve) will reduce the required pressure difference. If the BPV is adjusted too loose the valve will open as soon as you let up off the throttle. It may even open during acceleration at higher boost pressures. If the BPV is adjusted too tight, the valve may not open soon enough (or at all) between shifts or when slowing. This may cause compressor surge which you should be able to hear as a "WHEw Whew whew" noise. When the valve is adjusted properly it should make a small noise as the air rushes through it into the intake hose after the throttle plate closes, such as when you shift gears or decelerate. GReddy recommends adjusting the BOV as tight as possible without causing compressor surge.

Problems:

- The GReddy Type S BOV is known to interfere with the shift cables for the 6-speed transaxle in 1994 and newer 3000GT and Stealth AWD models. The BOV must be tied out of the way of the cables.

- As the DSMtalk thread explains, the internal membranes can become damaged and must be repaired or replaced.

- An adapter is required to attach the GReddy BOV to the large hose connected to the Y-pipe. This hose has an inside diameter of about 1.25 inches or about 32 mm. 3SX Performance sells these, as do others (see Rob Beck on the 3si.org message board).

Installation:

Remove the air filter and MAS. Remove the old BPV. Attach the adapter to the GReddy BOV; make sure it seals well to the BOV. Install the GReddy BOV. The small hose that connects the purple cap to the plenum ("after" the throttle body) should not be connected to anything else. Do not cap or connect a hose to the angled nipple on the silver BOV body. Install the air filter and MAS.

Page last updated June 12, 2005.